2618 bar stock

Tensile strength ≥ 420 MPa, elongation ≥ 7%, the alloy maintains good mechanical properties at high temperatures, suitable for high-temperature environments such as impellers in turbochargers.

Product Classification:

Key words:

2618 aluminum alloy

china 2618 aluminum alloy

2618 Bar Stock: High - Performance Material for Diverse Applications

2618 bar stock is a remarkable material that has found extensive use in various industries due to its outstanding properties.

1. Composition and Structure

The 2618 alloy, from which the bar stock is made, typically consists of aluminum as the base metal, along with other alloying elements. It contains elements such as copper, magnesium, and nickel. The copper content provides enhanced strength and heat - resistance. Magnesium improves the formability and also contributes to the overall strength of the material. Nickel further enhances the high - temperature properties of the 2618 bar stock. This carefully balanced composition results in a microstructure that gives the bar stock its unique characteristics.

2. High - Strength Characteristics

One of the most prominent features of 2618 bar stock is its high strength. It has excellent tensile strength, which makes it suitable for applications where the material needs to withstand significant mechanical loads. For example, in the aerospace industry, it can be used for components such as aircraft engine parts and structural members. The high strength - to - weight ratio of 2618 bar stock is also a great advantage. It allows for the design of lightweight yet strong structures, which is crucial for applications where weight reduction is of prime importance, like in the automotive and aerospace sectors.

3. Heat - Resistance

The 2618 bar stock exhibits remarkable heat - resistance properties. It can maintain its mechanical properties at elevated temperatures, which is essential for applications in high - temperature environments. In the manufacturing of engine components, for instance, where temperatures can reach extremely high levels during operation, 2618 bar stock can perform reliably. This heat - resistance also makes it suitable for applications in the power generation industry, where components need to withstand the heat generated during power production processes.

4. Machinability

Another important aspect of 2618 bar stock is its good machinability. It can be easily cut, drilled, and shaped using standard machining processes. This allows manufacturers to produce complex components with relative ease. The smooth surface finish that can be achieved during machining is also beneficial for applications where surface quality is important, such as in precision engineering and the production of high - end components.

5. Corrosion - Resistance

Although not as highly corrosion - resistant as some other alloys specifically designed for extreme corrosive environments, 2618 bar stock still offers a certain level of corrosion - resistance. This is sufficient for many applications where it is not exposed to highly corrosive substances on a regular basis. However, appropriate surface treatments can be applied to further enhance its corrosion - resistance if required.

6. Applications

The 2618 bar stock has a wide range of applications. In the aerospace field, it is used for manufacturing turbine blades, engine casings, and other critical components. In the automotive industry, it can be used for parts such as pistons and cylinder heads. It also finds applications in the manufacturing of industrial machinery, where high - strength and heat - resistant components are required. Additionally, in the sports equipment industry, it can be used for high - performance components due to its strength and lightweight properties.

In conclusion, 2618 bar stock is a versatile and high - performance material that offers a combination of strength, heat - resistance, machinability, and other beneficial properties, making it an ideal choice for a variety of industrial applications.

Previous:

Next:

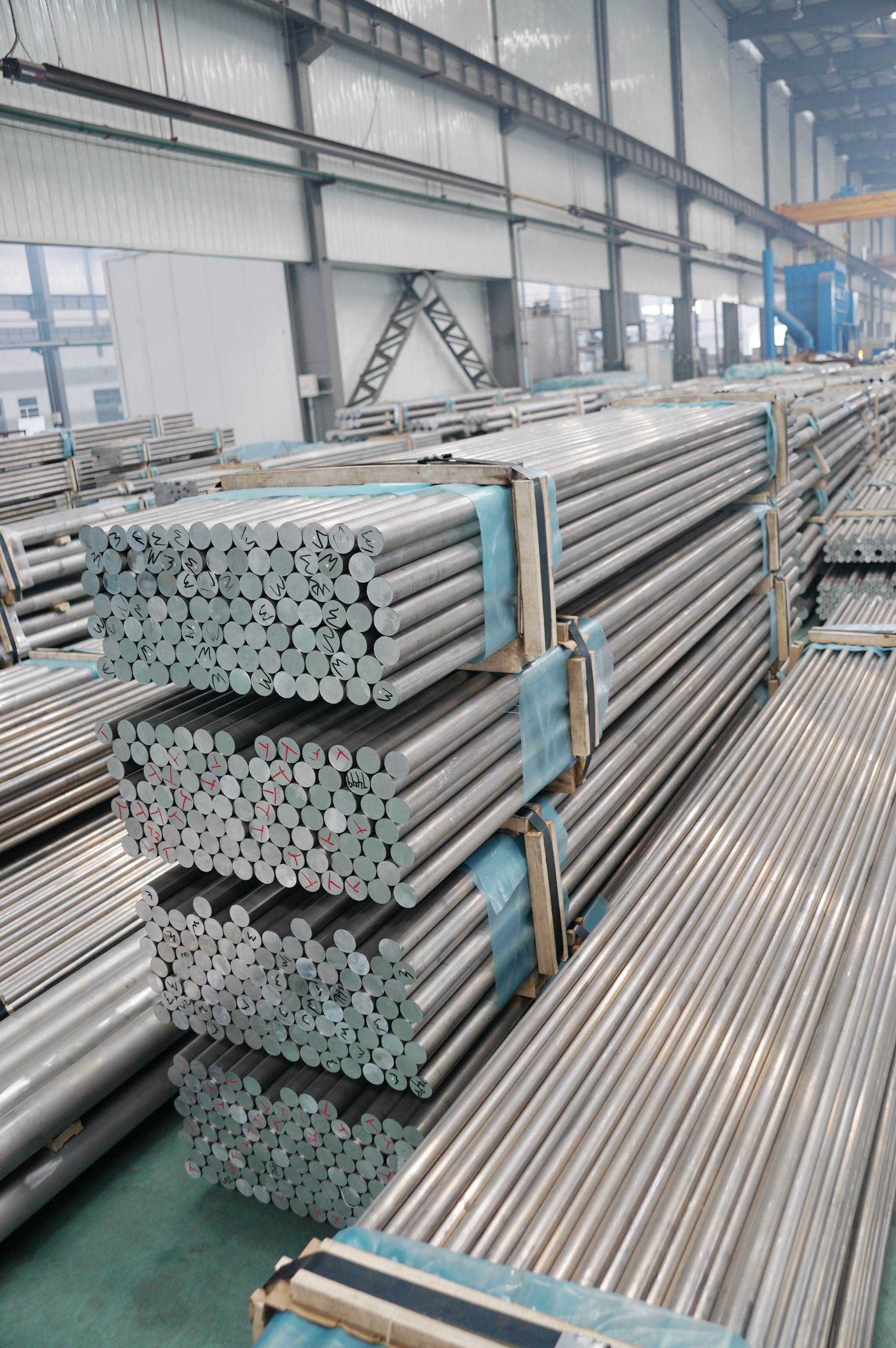

Covering the main brands of 1-7 series aluminum alloys, the products are high-precision seamless tubes, bars, profiles, drawn-rolled tubes, forgings, etc., which are widely used in new energy vehicles, aerospace, ships, drones, robots, Security video surveillance, vehicle-mounted Internet of Things and other fields.

Packing And Delivery

With over 20 years of experience in the aluminum alloy material industry, serving a wide range of customers across various sectors, we have been producing this product for many years. All customer orders are completed by our professional team, dedicated to providing you with the highest quality products and services.

Covering the main grades of 1-7 series aluminum alloys, our products include high-precision seamless tubes, rods, profiles, drawn tubes, forgings, and more. They are widely used in new energy vehicles, aerospace, ships, UAVs, robots, security video surveillance, in-vehicle Internet of Things, and other fields.

Customer Visit

We sincerely welcome you to our factory and company to negotiate business. We look forward to establishing long-term business relations with your company. If you are interested in any of our products, please feel free to contact us for more information.

We warmly invite our valued clients and partners to visit our facilities and witness our operations in person.

A guided tour will allow you to:

▏ See our state-of-the-art manufacturing processes

▏ Meet our expert team members face-to-face

▏ Gain deeper insights into our quality control measures

▏ Discuss your specific requirements in our dedicated meeting spaces.

Client Feedback

Our reliable Quality Inspection Capabilities, comprehensive Testing Reports & Certifications, and impeccable after-sales service system have earned us praise from customers both domestically and internationally. We sincerely hope to establish good business relations with your company.

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!