Workpiece

This newest aluminum alloy forging from China delivers superior strength and precision for high-performance industrial components. Combining advanced metallurgy with precision forging techniques, it offers the structural integrity and reliability of a quality aluminum alloy forging, providing excellent solutions for automotive, aerospace, and machinery applications.

Product Classification:

Key words:

aluminum alloy forging

Parameter

| Alloy Grade | State | Die forging | Free forging | ||||

| Projected area(cm) | Thicknes(mm) | Minimum wall thicknessmm(mm) | Length(mm) | Width(mm) | Thicknes(mm) | ||

| 5052、5083 | O、H112 | 20~400 | 20~150 | 5 | 20~500 | 20~300 | 20~150 |

| 2A11、2A12、2A14 | T4 | ||||||

| 2014、2017、2A70、4032、2618、2618A、7A04、7A09、7075、6061、6A02、6082 | T6 | ||||||

Product Introduction:

This newest aluminum alloy forging from China provides manufacturers with exceptional mechanical properties through its refined grain structure that enhances strength, toughness, and fatigue resistance. The precision forging process ensures optimal material distribution and eliminates porosity, resulting in workpieces with consistent performance and dimensional accuracy. Engineers benefit from the excellent weight-to-strength ratio that allows for lightweight yet durable components, reducing overall system weight while maintaining structural integrity in demanding applications.

Manufactured to exacting standards, this quality aluminum alloy forging maintains superior corrosion resistance and thermal stability across various operating conditions. The smooth surface finish and precise tolerances reduce secondary machining requirements, streamlining production processes and lowering manufacturing costs. As the newest aluminum alloy forging from China, it represents advanced forging technology that delivers the trusted performance of a quality aluminum alloy forging while incorporating material innovations that enhance component durability and performance for precision engineering applications.

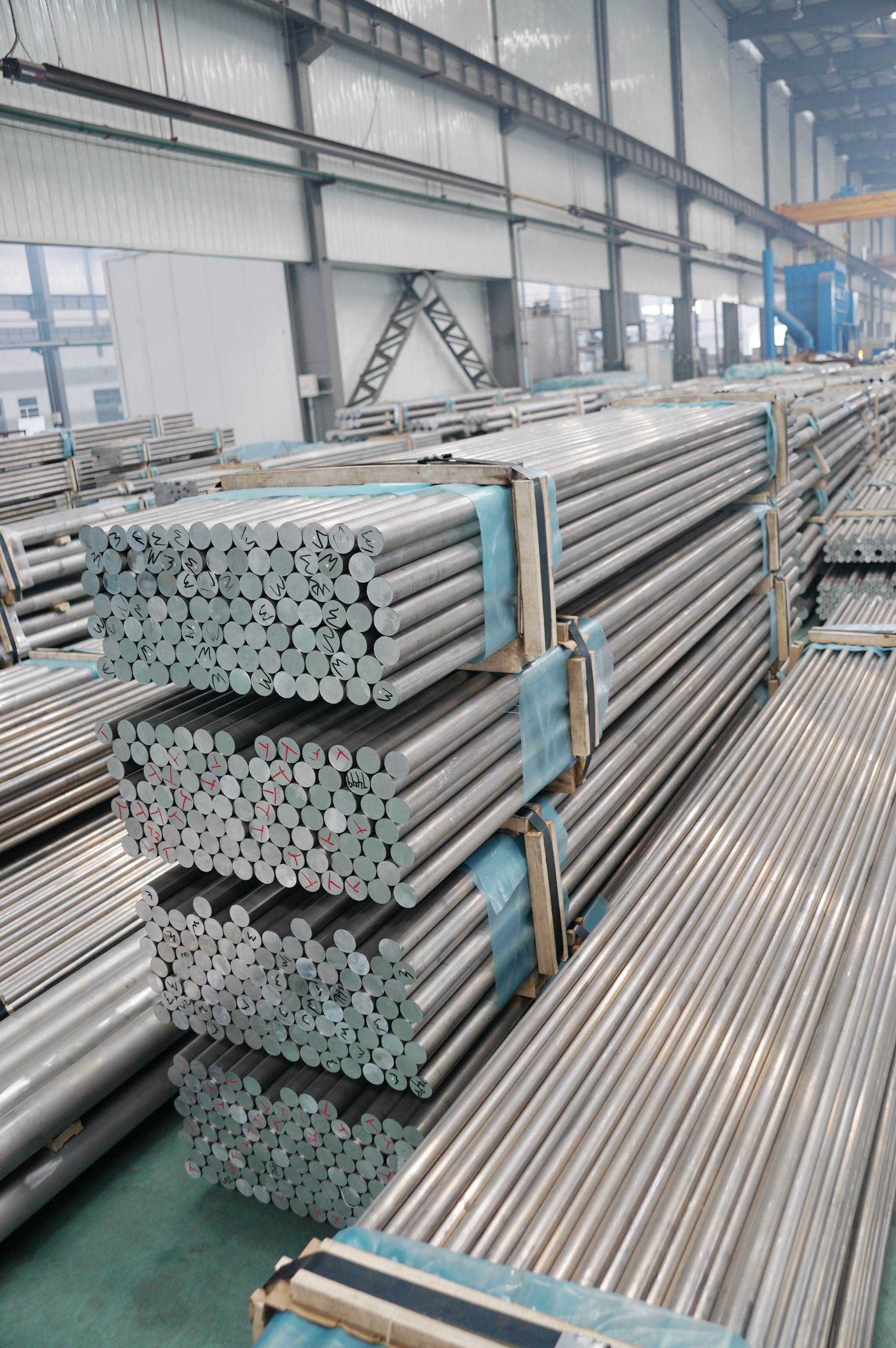

Covering the main brands of 1-7 series aluminum alloys, the products are high-precision seamless tubes, bars, profiles, drawn-rolled tubes, forgings, etc., which are widely used in new energy vehicles, aerospace, ships, drones, robots, Security video surveillance, vehicle-mounted Internet of Things and other fields.

Packing And Delivery

With over 20 years of experience in the aluminum alloy material industry, serving a wide range of customers across various sectors, we have been producing this product for many years. All customer orders are completed by our professional team, dedicated to providing you with the highest quality products and services.

Covering the main grades of 1-7 series aluminum alloys, our products include high-precision seamless tubes, rods, profiles, drawn tubes, forgings, and more. They are widely used in new energy vehicles, aerospace, ships, UAVs, robots, security video surveillance, in-vehicle Internet of Things, and other fields.

Customer Visit

We sincerely welcome you to our factory and company to negotiate business. We look forward to establishing long-term business relations with your company. If you are interested in any of our products, please feel free to contact us for more information.

We warmly invite our valued clients and partners to visit our facilities and witness our operations in person.

A guided tour will allow you to:

▏ See our state-of-the-art manufacturing processes

▏ Meet our expert team members face-to-face

▏ Gain deeper insights into our quality control measures

▏ Discuss your specific requirements in our dedicated meeting spaces.

Client Feedback

Our reliable Quality Inspection Capabilities, comprehensive Testing Reports & Certifications, and impeccable after-sales service system have earned us praise from customers both domestically and internationally. We sincerely hope to establish good business relations with your company.

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!