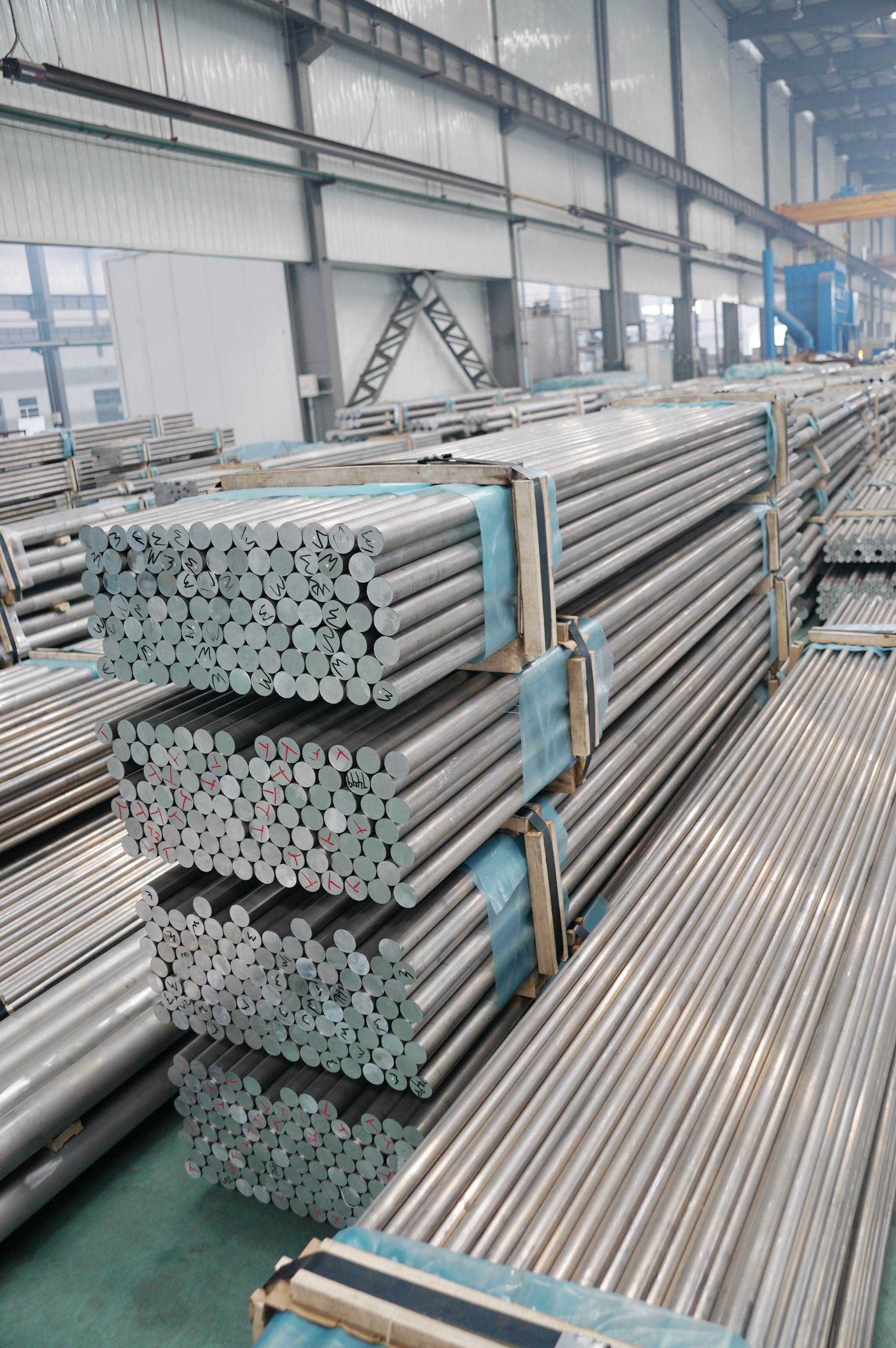

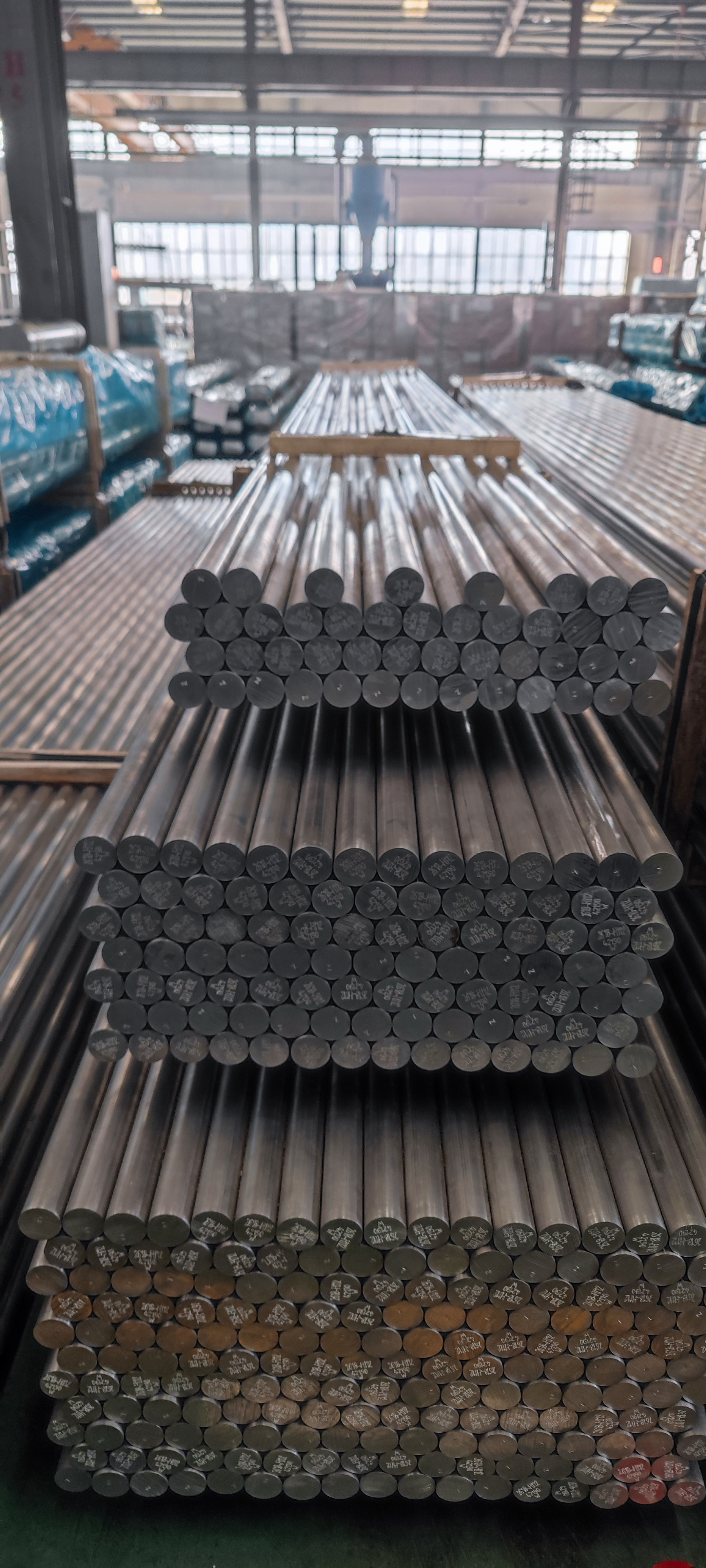

2618 bar stock

Tensile strength ≥ 420 MPa, elongation ≥ 7%, the alloy maintains good mechanical properties even at high temperatures, suitable for high-temperature environments such as impellers in superchargers.

Product Classification:

Key words:

2618 aluminum alloy

2618 bar stock is an aluminum - based alloy.

Properties

Strength and Heat Resistance

It has relatively high strength, especially at elevated temperatures. This makes it suitable for applications where components need to withstand mechanical loads at moderately high temperatures. For example, in some parts of aircraft engines that are exposed to heat during operation but also need to bear certain mechanical stresses.

Composition

The alloy typically contains elements like copper (Cu), magnesium (Mg), and some other minor elements. The copper content contributes to its strength and heat - resistant properties. Magnesium helps in improving the alloy’s mechanical properties and also has some influence on its corrosion resistance.

Machinability

It can be machined using standard machining techniques, although special considerations may be needed due to its alloy composition. Machining parameters such as cutting speed, feed rate, and depth of cut need to be optimized to achieve good surface finish and dimensional accuracy.

Applications

It is often used in the aerospace industry for manufacturing components such as engine parts, structural elements in aircraft where high - temperature strength and good mechanical properties are required. It can also be used in some high - performance automotive applications where heat - resistant and strong components are needed.

Parameter

| Alloy grade | State | Round rod(mm) | Square stick(mm) |

Inner diameter of hexagonal rod(mm) |

Width/Thickness(mm) | Thickness(mm) | Circumscribed circle(mm) |

| HAS、HAS-2、4032 | O、H112 T6、T6xx |

Φ14~Φ300 | 14x14~200x200 | Φ14~Φ260 | ≤30 | ≥3.0 | 30~300 |

| 6061、6A02、6082 | |||||||

| 5052、5083 | O、H112 | ||||||

| 2A11、2A12、2017 | O、H112 T4、T351 |

Φ20~Φ300 | 20x20~200x200 | Φ20~Φ260 | ≤20 | ≥4.0 | 30~300 |

| 2014、2A14、2A70、2618、2618A、7A04、7A09、7075 | O、H112 T6、T6xx |

| Diameter(mm) | Allowable deviation of extruded bars(mm) | Draw bars(mm) | ||||

| A | B | C | D | E | Ordinary grade | |

| 14-18 | -0.43 | -0.70 | -1.10 | -1.30 | ±0.22 | ±0.08 |

| 18-25 | -0.50 | -0.80 | -1.20 | -1.45 | ±0.25 | ±0.08 |

| 25-28 | -0.52 | -0.84 | -1.30 | -1.50 | ±0.28 | ±0.10 |

| 28-40 | -0.60 | -0.95 | -1.50 | -1.80 | ±0.30 | ±0.10 |

| 40-50 | -0.62 | -1.00 | -1.60 | -2.00 | ±0.35 | |

| 50-65 | -0.70 | -1.15 | -1.80 | -2.40 | ±0.40 | |

| 65-80 | -0.74 | -1.20 | -1.90 | -2.50 | *0.45 | |

| 80-100 | -0.95 | -1.35 | -2.10 | -3.10 | ±0.55 | |

| 100-120 | -1.00 | -1.40 | -2.20 | -3.20 | ±0.65 | |

| 120-150 | -1.25 | -1.55 | -2.40 | -3.70 | ±0.80 | |

| 150-180 | -1.30 | -1.60 | -2.50 | -3.80 | ±1.00 | |

| 180-220 | -1.85 | -2.80 | -4.40 | ±1.15 | ||

| 220-250 | -1.90 | -2.90 | -4.50 | ±1.25 | ||

| 250-270 | -2.15 | -3.20 | -5.40 | ±1.30 | ||

| 270-300 | -2.20 | -3.30 | -5.50 | ±1.50 | ||

Previous:

Next:

Covering the main brands of 1-7 series aluminum alloys, the products are high-precision seamless tubes, bars, profiles, drawn-rolled tubes, forgings, etc., which are widely used in new energy vehicles, aerospace, ships, drones, robots, Security video surveillance, vehicle-mounted Internet of Things and other fields.

Packing And Delivery

With over 20 years of experience in the aluminum alloy material industry, serving a wide range of customers across various sectors, we have been producing this product for many years. All customer orders are completed by our professional team, dedicated to providing you with the highest quality products and services.

Covering the main grades of 1-7 series aluminum alloys, our products include high-precision seamless tubes, rods, profiles, drawn tubes, forgings, and more. They are widely used in new energy vehicles, aerospace, ships, UAVs, robots, security video surveillance, in-vehicle Internet of Things, and other fields.

Customer Visit

We sincerely welcome you to our factory and company to negotiate business. We look forward to establishing long-term business relations with your company. If you are interested in any of our products, please feel free to contact us for more information.

We warmly invite our valued clients and partners to visit our facilities and witness our operations in person.

A guided tour will allow you to:

▏ See our state-of-the-art manufacturing processes

▏ Meet our expert team members face-to-face

▏ Gain deeper insights into our quality control measures

▏ Discuss your specific requirements in our dedicated meeting spaces.

Client Feedback

Our reliable Quality Inspection Capabilities, comprehensive Testing Reports & Certifications, and impeccable after-sales service system have earned us praise from customers both domestically and internationally. We sincerely hope to establish good business relations with your company.

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!