Product Center

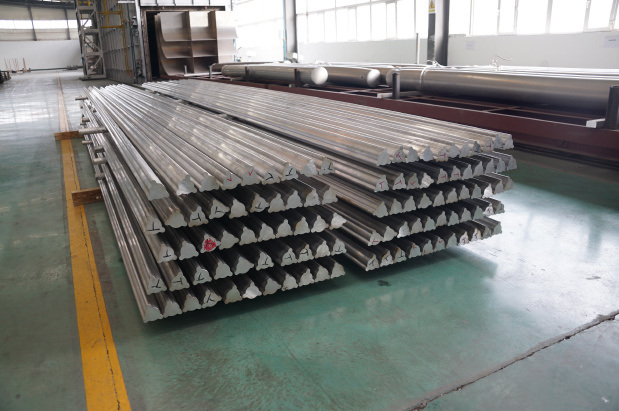

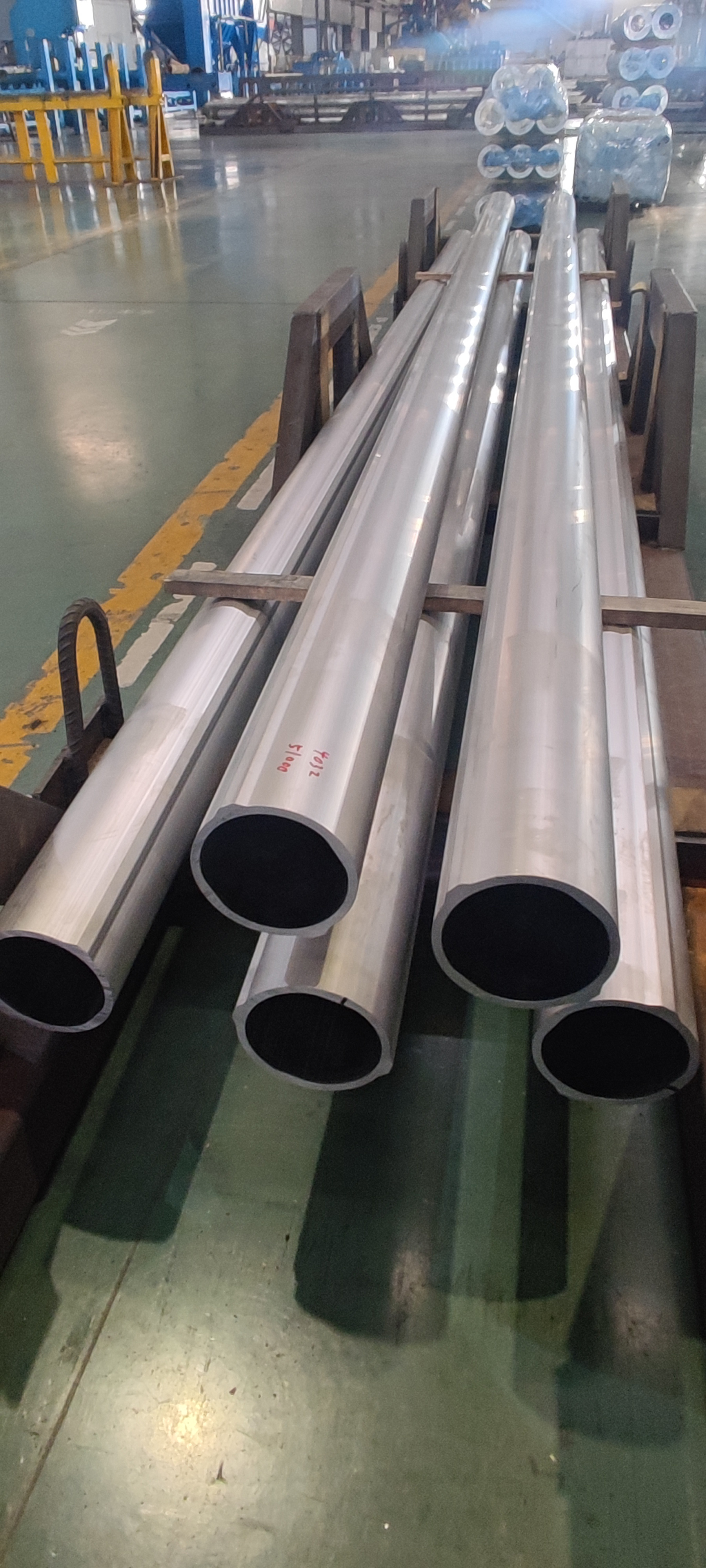

Covering the main grades of 1-7 series aluminum alloys, the products are high-precision seamless tubes, rods, profiles, drawn tubes, forgings, etc., widely used in new energy vehicles, aerospace, ships, UAVs, robots, security video surveillance, in-vehicle Internet of Things and other fields.

Scroll Down

Tensile strength ≥ 420 MPa, elongation ≥ 7%, the alloy maintains good mechanical properties at high temperatures, suitable for high-temperature environments such as impellers in turbochargers.

Tensile strength ≥ 420 MPa, elongation ≥ 7%, the alloy maintains good mechanical properties even at high temperatures, suitable for high-temperature environments such as impellers in superchargers.

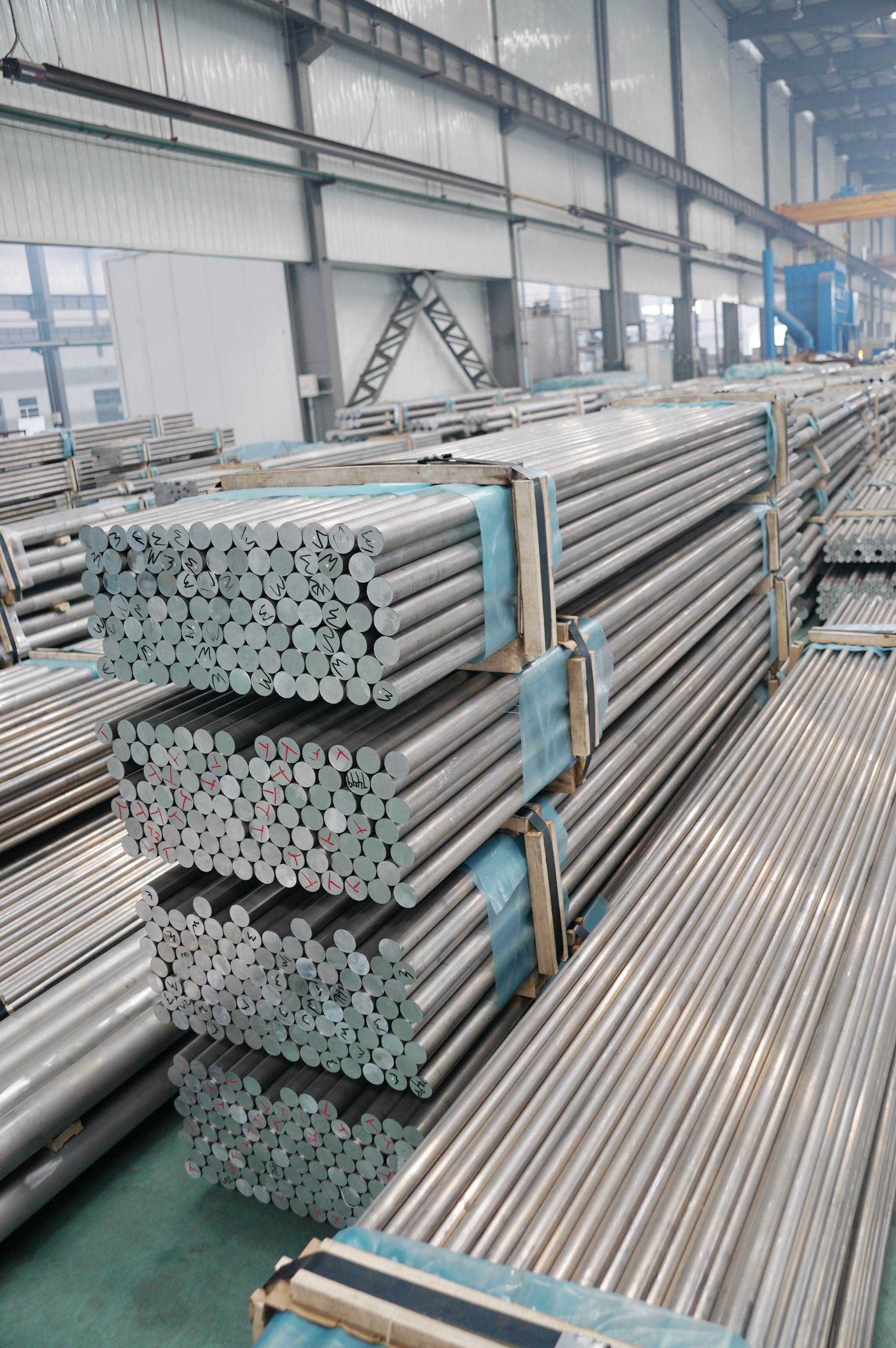

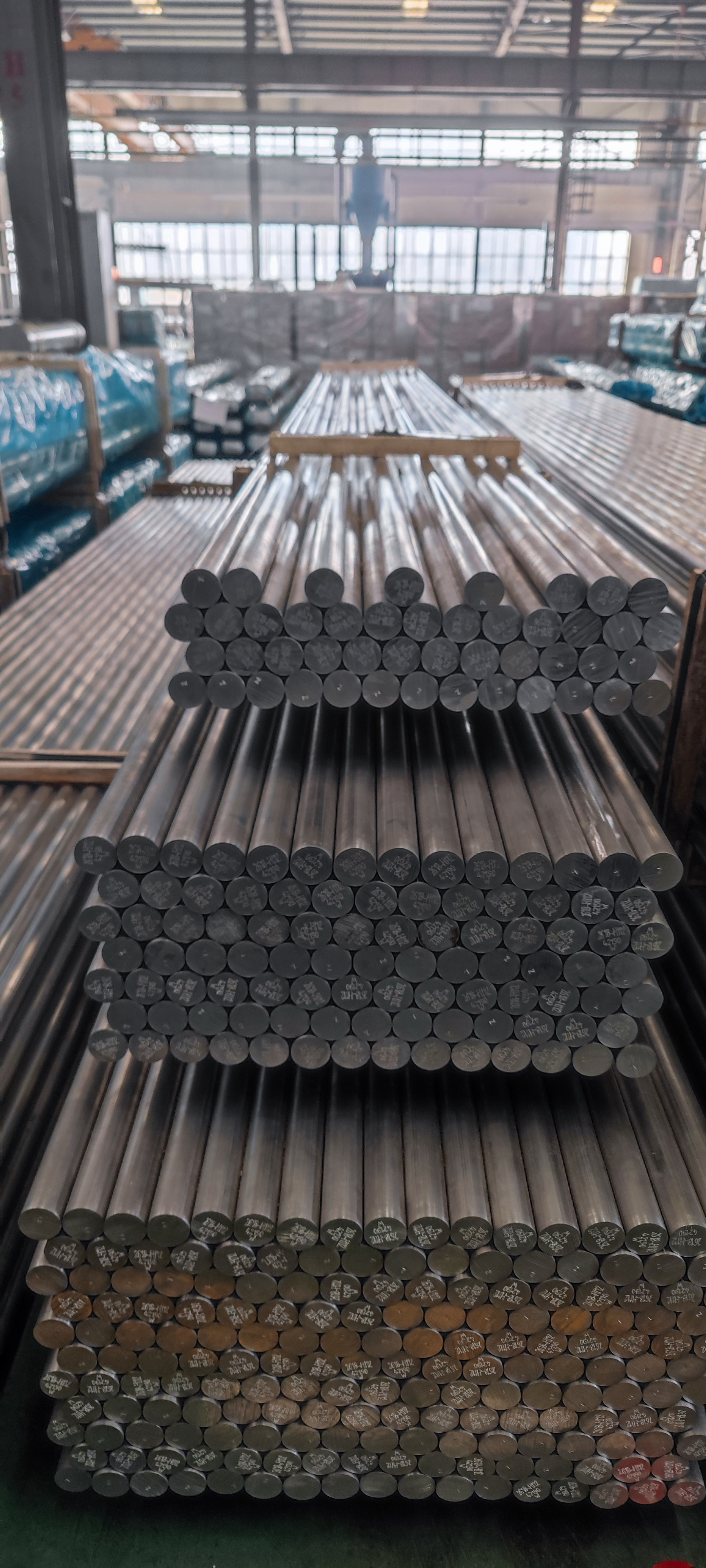

Production range: φ10-φ350; excellent machinability, virtually no coarse crystals ensure superior oxidation.

Can be produced from φ10-φ350; has good processing performance, almost no coarse crystals can guarantee excellent oxidation effect.

We can produce from φ10 to φ350; it has good processing performance, with virtually no coarse crystals to ensure excellent oxidation effect.

Covers high-performance alloys such as 1060/2A12/2024/2A11/7075/6061/6082/5083, with no weld lines, uniform structure and properties, and high dimensional accuracy; precise control of wall thickness, concentricity, and internal and external diameter tolerances.

High-silicon aluminum alloy, with wear-resistant and heat-resistant properties, is widely used in the stator and rotor of new energy vehicles and air conditioning pistons. Our company's 4032 aluminum extrusion rod has a tensile strength ≥ 400 MPa, yield strength ≥ 360 MPa, and elongation ≥ 6%.

AHS-2 material has a tensile strength ≥ 430 MPa. Both have eutectic silicon less than 0.02 mm, and the primary silicon is point-like distributed, reaching the advanced level of the industry.

High-silicon aluminum alloy, with wear-resistant and heat-resistant properties, is widely used in the stator and rotor discs of new energy vehicles and air conditioning pistons. Our company's 4032 aluminum extrusion rods have a tensile strength ≥400MPa, yield strength ≥360MPa, and elongation ≥6%. The AHS-2 material has a tensile strength ≥430MPa. Both have eutectic silicon below 0.02MM, with primary silicon in a dot-like distribution, reaching an advanced industry level.

● 2024 aluminum alloy is a high-strength aluminum alloy. It exhibits excellent mechanical properties, especially in the T3 and T4 states, making it suitable for high-load applications. It features small grains and virtually no coarse grain rings (national standard: ordinary grade ≤8mm, high-precision grade ≤3mm).

● Performance Advantages: Tensile Strength: 380-560; Yield Strength: 260-445; Elongation: 11-17, National Standard 6-10

If you are interested in our products, please leave your E-mail and we will contact you as soon as possible. Thank you!